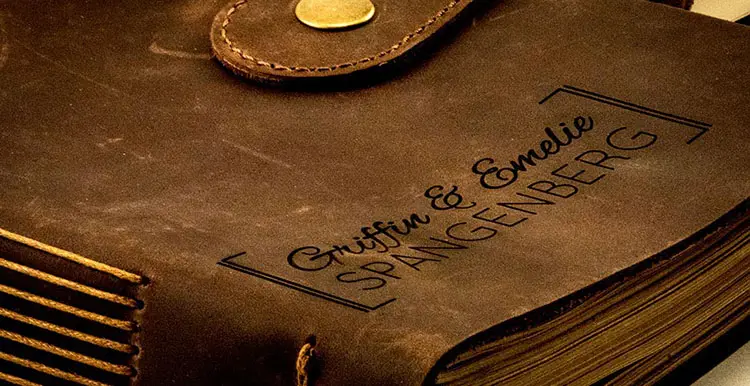

LASER MARKING LEATHER: THE FUTURE OF CUSTOMIZATION

Leather has always been an essential material for fashion and accessories, and it has always been a symbol of luxury. However, the process of customizing leather has been limited to traditional methods, such as embossing, engraving, and printing.

These methods have their limitations and are not always able to provide the desired level of detail or customization. Mac Laser’s laser marking technology can change the limits of these custom leathers and become the future of customization.

RECOMMENDED LASER SOLUTIONS

MQC-T CO2 Laser Marking Machine

G series Flying CO2 Laser Marking Machine

Why Choose Laser Machines for Leather Marking?

HIGH PRECISION

One of the biggest advantages of laser marking leather is the high precision it offers. Laser marking machines can create highly detailed designs and lettering, which is not always possible with traditional methods. Laser marking machines can also create consistent marks or engravings, which is important for branding and logo design.

VERSATILITY

Laser marking is highly versatile and can be used on a wide range of leather products, including shoes, belts, bags, and wallets. Laser marking can also be used on different types of leather, such as full-grain, top-grain, and corrected-grain leather.

DURABILITY

Laser marking creates a permanent mark or engraving on the leather, which is highly durable and long-lasting. The mark or engraving will not fade or wear off over time, making it ideal for branding and logo design.

TIME-SAVING

Laser marking is a fast and efficient process, which can save time and reduce costs. Laser marking machines can create multiple marks or engravings at once, which is important for large-scale production.

Laser marking is a popular leather marking technique, especially useful for intricate logos or patterns. For leather, precise and detailed designs can be produced without damage or deformation.

Leather is used to make a wide variety of products, including clothing, shoes, accessories, furniture, and even car interiors.

Types of Laser Marking

– Surface Marking

Surface marking creates a shallow mark or engraving on the surface of the leather, leaving the natural texture intact. This type of marking is often used for branding and logo design.

– Deep Engraving

Deep engraving removes a deeper layer of the leather, creating a more prominent mark or engraving. This type of marking is often used for creating intricate designs and patterns on leather products.

– Color Marking

Color marking uses a special laser that heats the surface of the leather, creating a color change without removing any material. This type of marking is often used for creating contrast and color in the design.

How to Choose the Right Laser Marking Machine

– Laser Type

There are different types of lasers used for marking leather, such as CO2, fiber, and Nd:YAG lasers. Each type of laser has its own advantages and disadvantages, depending on the application.

– Power

The power of the laser determines the speed and depth of the marking. Higher power lasers can mark deeper and faster, but they may also require more maintenance.

– Wavelength

The wavelength of the laser affects the type of material that can be marked. Different types of leather may require different wavelengths of lasers.

– Speed

The speed of the laser affects the efficiency and quality of the marking. Higher speed lasers can mark faster, but they may also require higher power.

– Cooling System

Laser marking machines require a cooling system to prevent overheating and maintain the quality of the marking. Different types of cooling systems may be required depending on the laser type and power.

FAQs

Can laser marking be used on all types of leather?

Laser marking can be used on most types of leather, but the quality and consistency of the marking may vary depending on the type of leather used.

Can laser marking machines be used for other materials besides leather?

Yes, laser marking machines can be used for marking a variety of materials, including metals, plastics, and ceramics.

Is laser marking more expensive than traditional methods of customizing leather?

The cost of laser marking machines can be higher than traditional methods, but laser marking offers many advantages over traditional methods, such as precision and durability.

Can laser marking be done on curved or irregular surfaces of leather products?

Yes, laser marking machines can be programmed to mark on curved or irregular surfaces of leather products. However, it may require more skill and experience to achieve consistent and high-quality marking.