In the world of printed circuit boards (PCBs), the importance of traceability, identification, and quality control cannot be overstated. Laser marking technology has emerged as an essential tool for these purposes.

In this comprehensive guide, we will explore what PCB laser marking machines are, how they work, their benefits, and their applications.

Table of Contents

Introduction

What are PCB Laser Marking Machines?

How do PCB Laser Marking Machines work?

Types of Laser Marking Machines

- Fiber Laser Marking Machines

- CO2 Laser Marking Machines

Advantages of PCB Laser Marking Machines

- High Precision and Accuracy

- Durable and Permanent Markings

- Versatility and Flexibility

- High-Speed Marking

- Cost-Effective

Applications of PCB Laser Marking Machines

- Automotive Industry

- Aerospace Industry

- Electronics Industry

Factors to Consider When Choosing a PCB Laser Marking Machine

- Laser Type and Wavelength

- Marking Speed

- Marking Area

- Marking Quality

- Ease of Use and Maintenance

Maintenance and Care of PCB Laser Marking Machines

- Regular Cleaning and Maintenance

- Laser Lens Maintenance

- Cooling System Maintenance

Common Challenges of PCB Laser Marking Machines

- Materials Compatibility

- Lack of Contrast

- Marking Depth and Width

Introduction

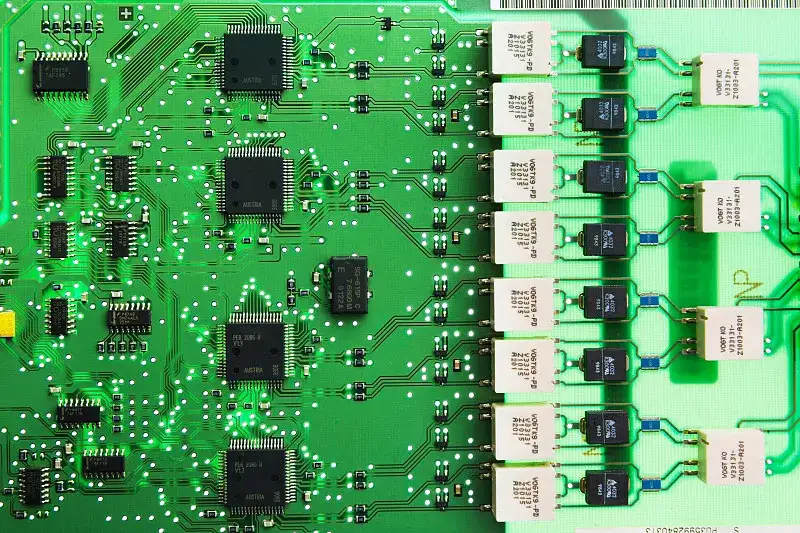

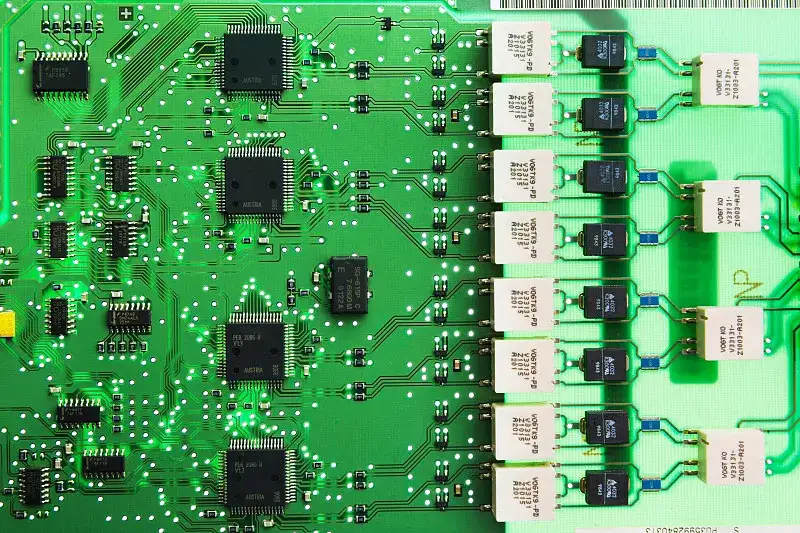

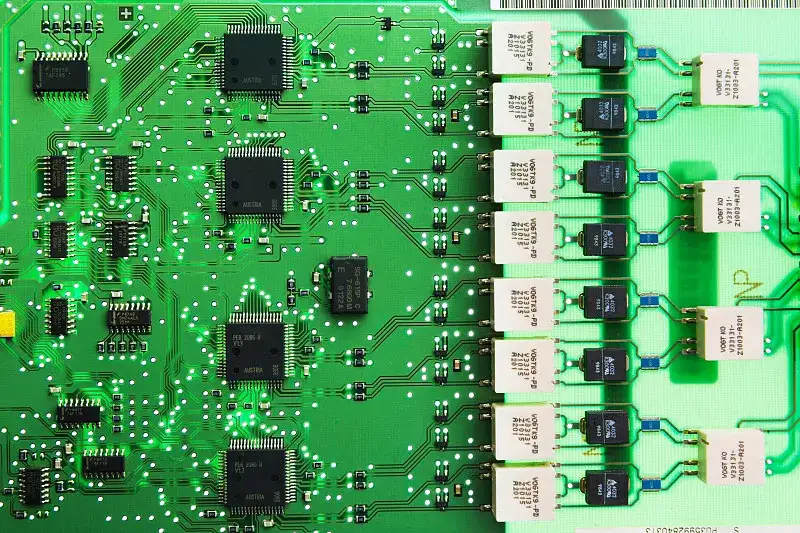

PCBs are essential components of modern electronics, and their importance continues to grow. With the rise of the Internet of Things (IoT), wearable devices, and other high-tech gadgets, the demand for PCBs is increasing rapidly.

To ensure quality, traceability, and identification, laser marking technology has become the go-to solution for many industries. This guide will take a deep dive into PCB laser marking machines.

What are PCB Laser Marking Machines?

Use laser technology to engrave or mark printed circuit boards. The laser beam creates a permanent mark on the surface of the PCB, which can include alphanumeric characters, logos, barcodes, QR codes, or any other design.

The marking process is precise, fast, and permanent, making it an ideal solution for traceability, identification, and quality control.

How do PCB Laser Marking Machines work?

Use a laser beam to remove or vaporize the top layer of the PCB material, leaving a permanent mark on the surface. The laser beam can be controlled by a computer, which allows for precise positioning and marking.

The laser beam can be directed using mirrors or other optical devices to mark any part of the PCB surface.

Types of Laser Marking Machines

Two main types of laser marking machines are used for PCBs: Fiber Laser Marking Machines and CO2 Laser Marking Machines.

Fiber Laser Marking Machines

Fiber Laser Marking Machines use a laser beam generated by a fiber optic cable. The laser beam is directed through a lens to the surface of the PCB, creating a high-contrast, high-quality mark. Fiber laser marking machines are ideal for marking metals and plastics.

CO2 Laser Marking Machines

CO2 Laser Marking Machines use a gas laser to create the marking. The laser beam is directed through a lens to the surface of the PCB, creating a permanent mark. CO2 laser marking machines are ideal for marking non-metallic materials, such as ceramics, glass, and some plastics.

Advantages of PCB Laser Marking Machines

PCB laser marking machines offer several advantages over other marking technologies. Some of the most significant benefits include the following:

- High Precision and Accuracy

Mac Laser’s laser marking machines are incredibly accurate and precise, which makes them ideal for marking small and intricate designs on PCBs. The laser beam can be directed to create marks as small as 0.01mm, allowing for high levels of detail and accuracy. - Durable and Permanent Markings

Laser markings created by laser marking machines are durable and permanent. They are resistant to wear, corrosion, and fading, which makes them ideal for applications where long-term identification and traceability are essential. - Versatility and Flexibility

PCB laser marking equipments are versatile and flexible, making them suitable for marking various materials, shapes, and sizes. They can mark on different materials, including metals, plastics, ceramics, and glass. They can also mark curved and irregular surfaces. - High-Speed Marking

Laser marking devices are fast and efficient, allowing for high-speed marking of large PCBs. This can save time and increase productivity in industries with large PCB volumes. - Cost-Effective

Laser marking machines for PCB are cost-effective over the long term. They require minimal maintenance, and the cost of consumables, such as laser diodes, is relatively low. They can also reduce the need for additional equipment, such as inkjet printers, which can save money on equipment and supplies.

Applications of PCB Laser Marking Machines

PCB laser marking machines are used in a wide range of industries, including:

- Automotive Industry

This machines used in the automotive industry to mark various components, including engine parts, chassis, and electronics. The markings can be used for traceability and quality control purposes. - Aerospace Industry

This machines used in the aerospace industry to mark critical components, such as turbine blades, fuel lines, and avionics. The markings can be used for identification, traceability, and safety purposes. - Electronics Industry

This machines used extensively in the electronics industry to mark PCBs, circuit boards, and other components. The markings can be used for identification, traceability, and quality control.

Factors to Consider When Choosing a PCB Laser Marking Machine

When choosing a PCB laser marking machine, there are several factors to consider, including:

- Laser Type and Wavelength

Different laser types and wavelengths are better suited for marking different materials. Choosing a laser marking machine compatible with the materials you will be marking is essential. - Marking Speed

The marking speed of a laser marking machine can affect production efficiency. Choosing a machine that can mark the required speed for your application is crucial. - Marking Area

The marking area of a laser marking machine can limit the size of the PCBs that can be marked. It is essential to choose a machine with a marking area that is suitable for your application. - Marking Quality

The quality of the laser marking can affect its readability and durability. Choosing a machine that can produce high-quality marks that are clear and permanent is crucial. - Ease of Use and Maintenance

A laser marking machine’s ease of use and maintenance can affect its efficiency and longevity. Choosing a machine that is easy to operate and maintain is essential.

Maintenance and Care of PCB Laser Marking Machines

Proper maintenance and care of PCB laser marking machines can ensure optimal performance and longevity. Some essential maintenance tasks include:

- Regular Cleaning and Maintenance

Keeping the machine clean and debris-free can prevent damage to the laser and other components. - Laser Lens Maintenance

The laser lens should be inspected and cleaned regularly to ensure the quality of the marking. Any dirt or debris on the lens can affect the clarity and precision of the marking. - Calibration

Laser marking machines require periodic calibration to ensure accurate and consistent marking. Calibration involves adjusting the laser power, focus, and other parameters to optimize the marking quality. - Replacement of Consumables

PCB laser marking machines require the replacement of consumables, such as laser diodes and lenses, over time. Following the manufacturer’s guidelines for replacing these components is essential to ensure optimal performance.

Conclusion

In conclusion, PCB laser marking are valuable for marking and identifying PCBs in various industries. They offer high precision and accuracy, durable and permanent markings, versatility and flexibility, high-speed marking, and cost-effectiveness.

When choosing a PCB laser marking machine, it is essential to consider factors such as laser type and wavelength, marking speed and area, marking quality, and ease of use and maintenance. Proper maintenance and care of the machine can ensure optimal performance and longevity.