Description

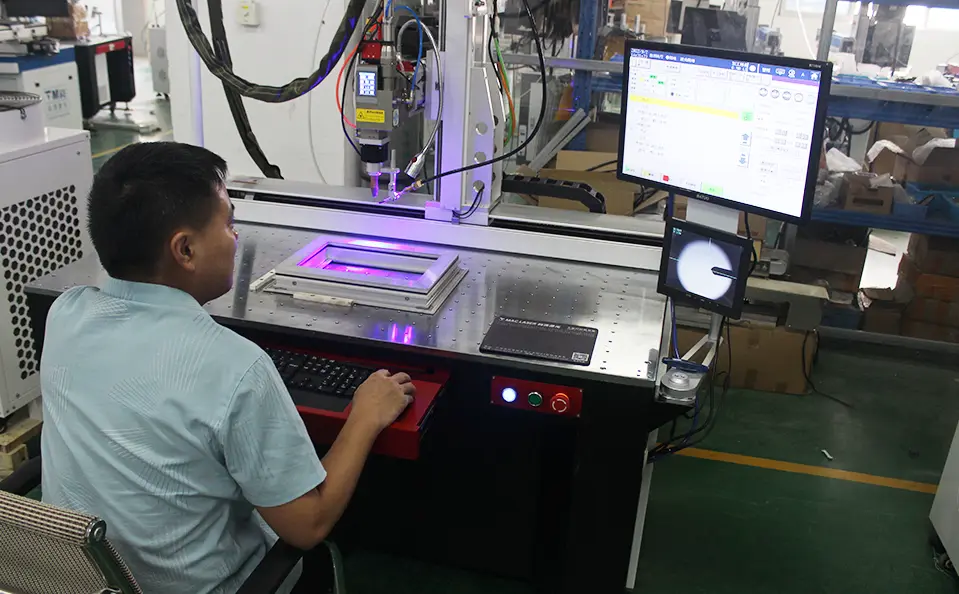

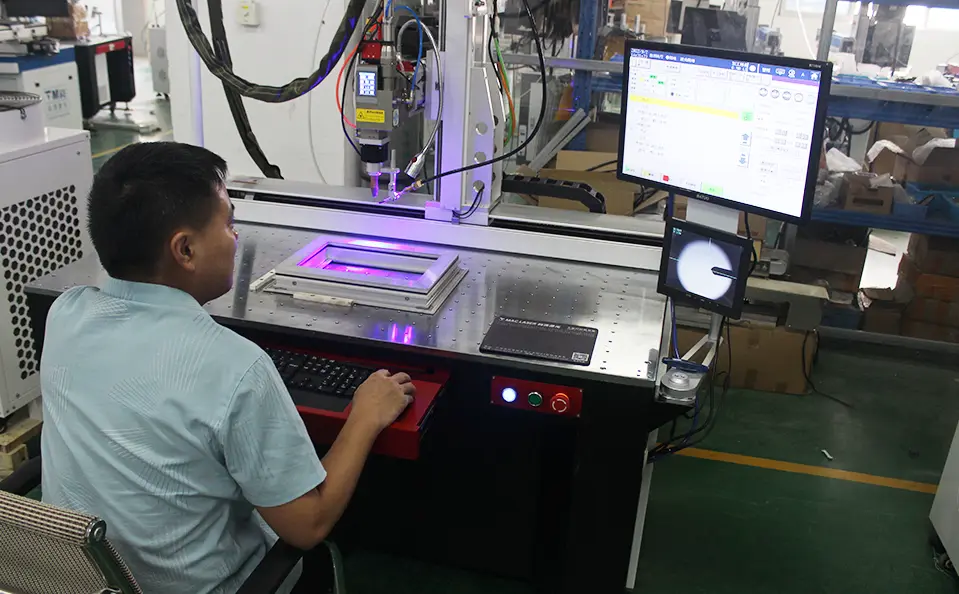

BOOST YOUR PRODUCTIVITY WITH LASER WELDING

centralized control switch

Centralized switch button, groove installation anti-collision design system has the function of centralized manual control. When the system is in manual control mode, it is possible to flexibly set the on-off status of each centralized loop.

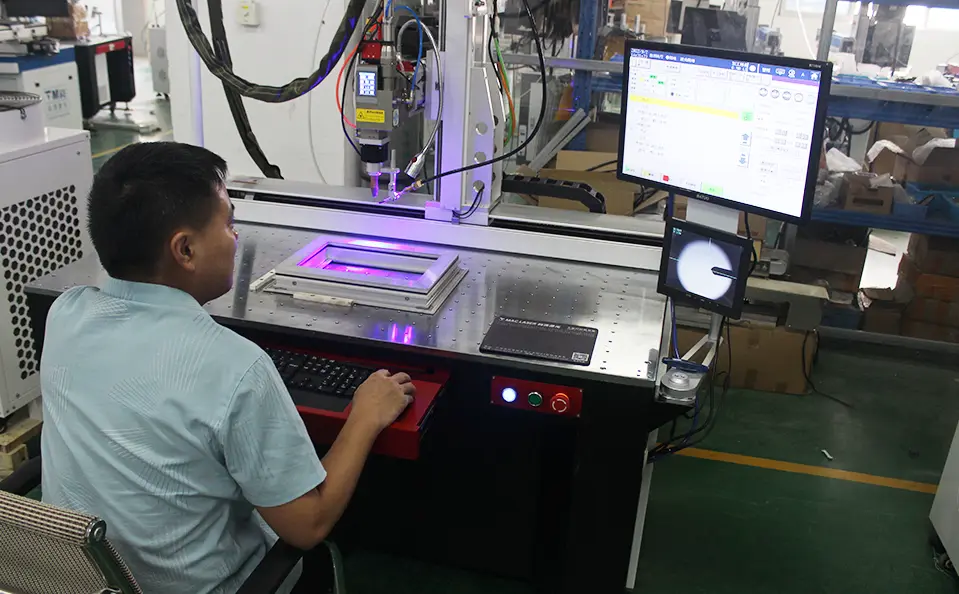

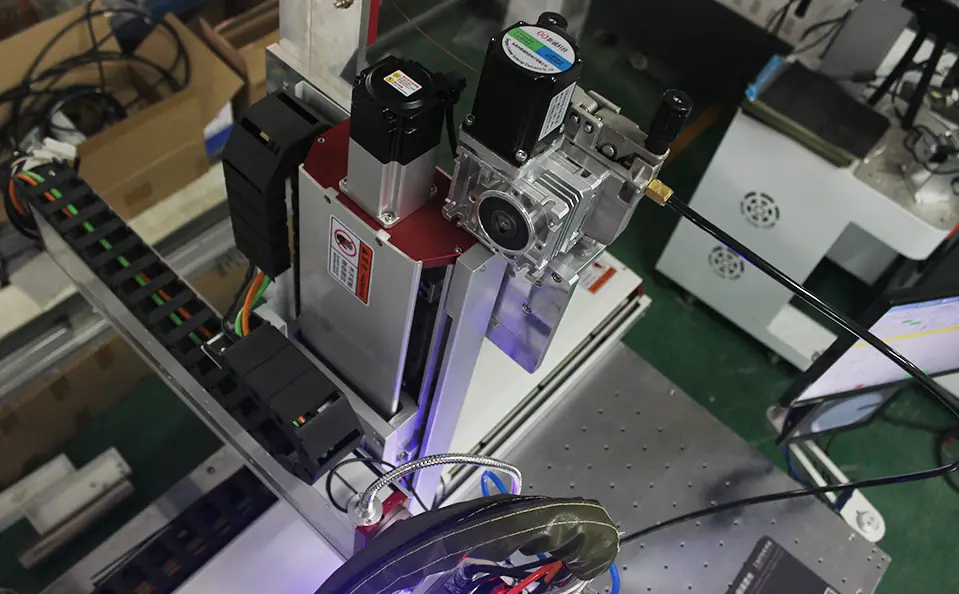

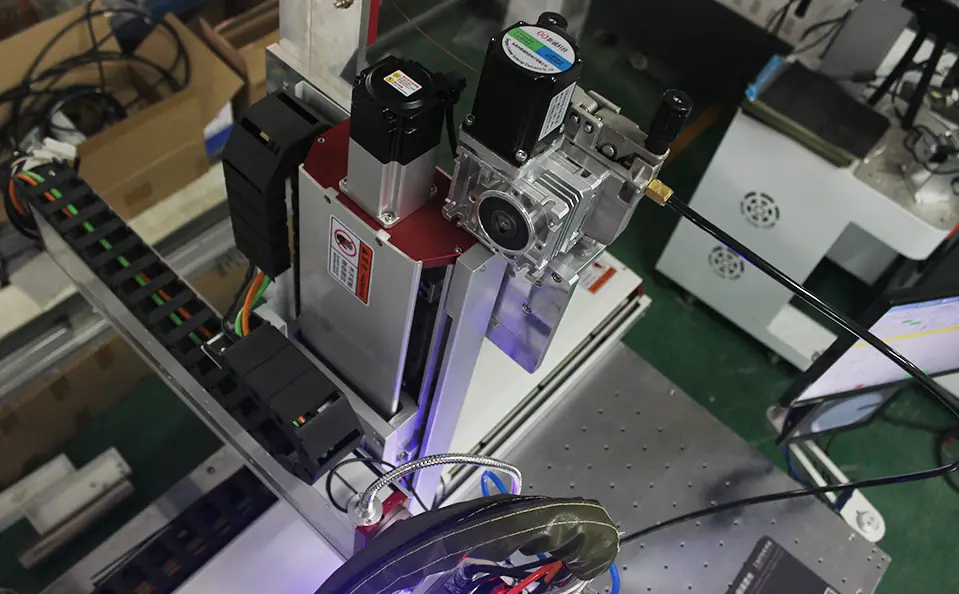

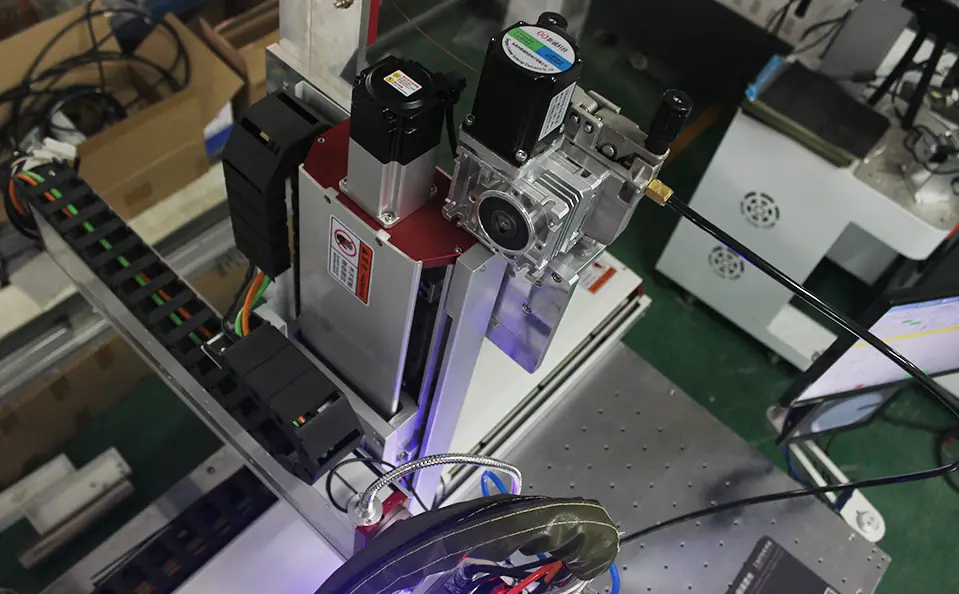

High stability YXZ module

High positioning accuracy, sensitive response, shockproof design; no need to manually move the product, with laser welding head for multi-angle, fully automatic welding, high stability, high reliability, 24-hour stable operation

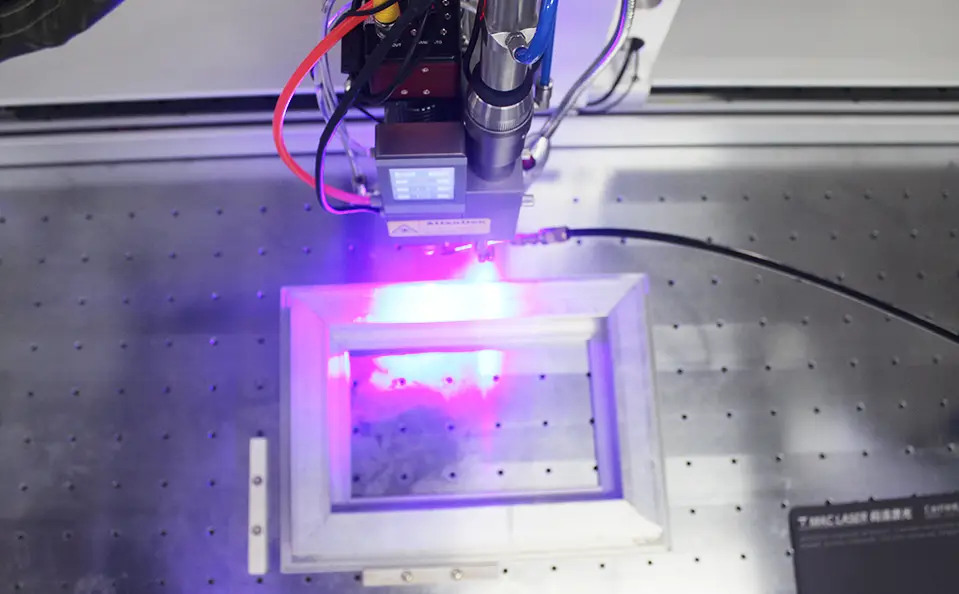

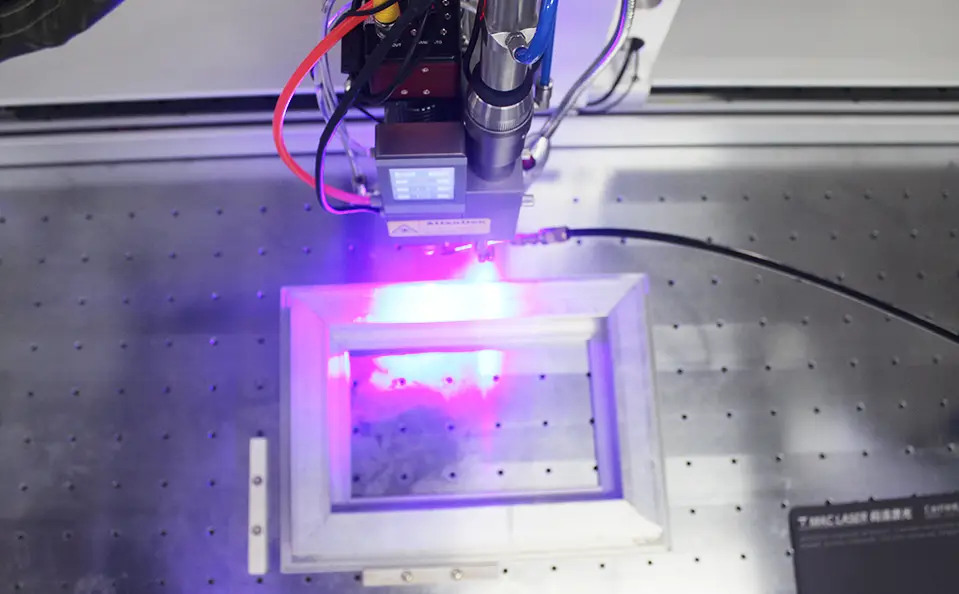

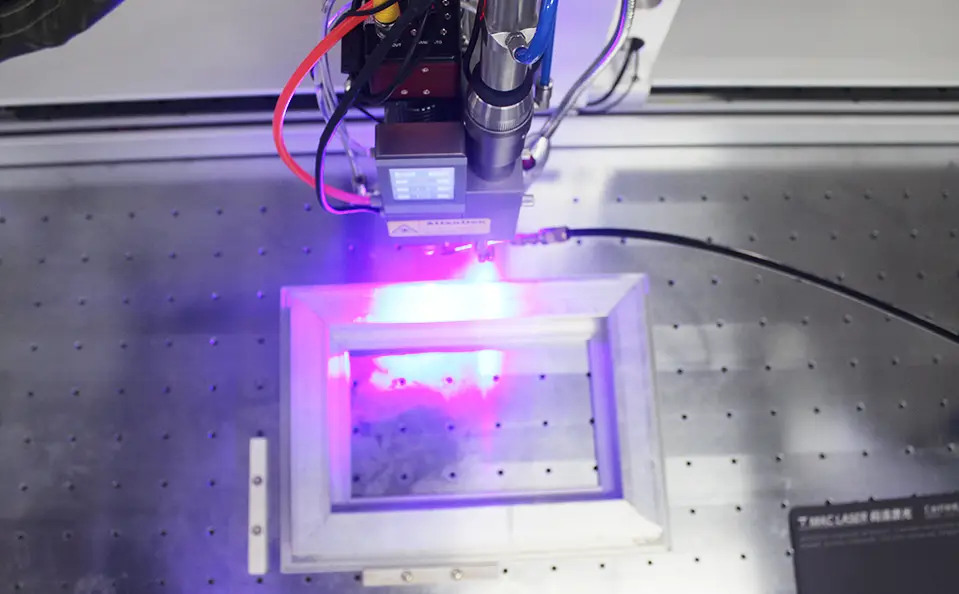

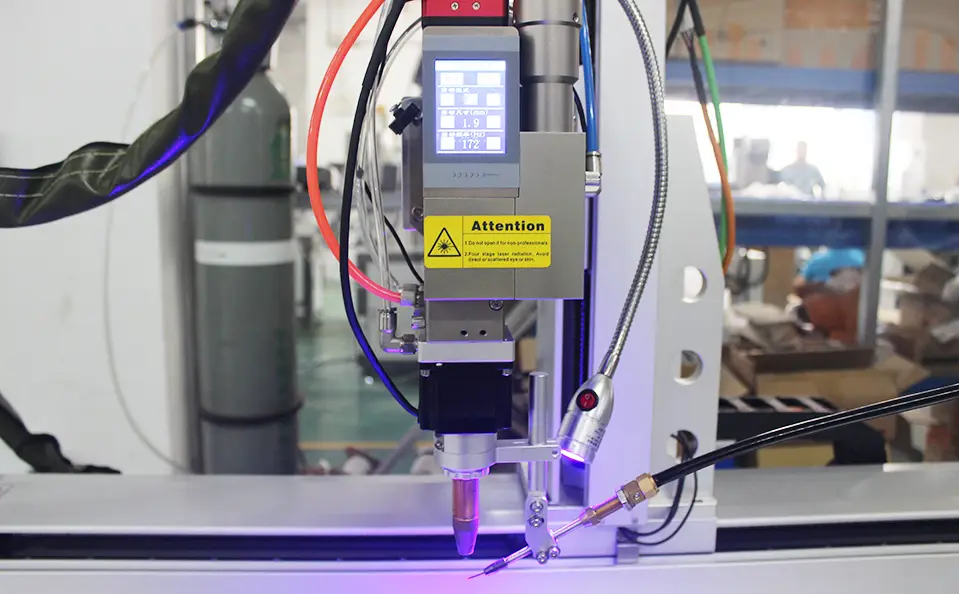

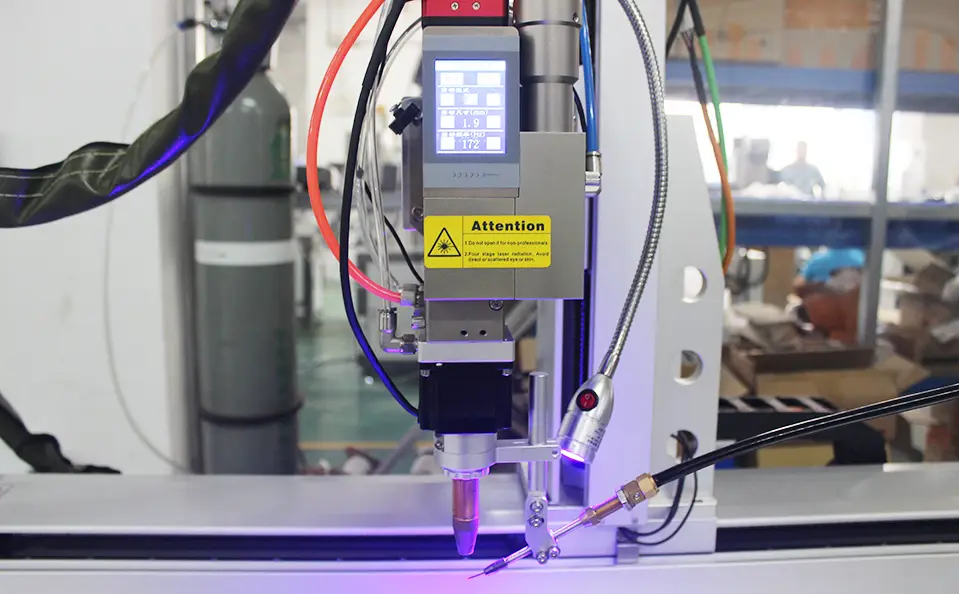

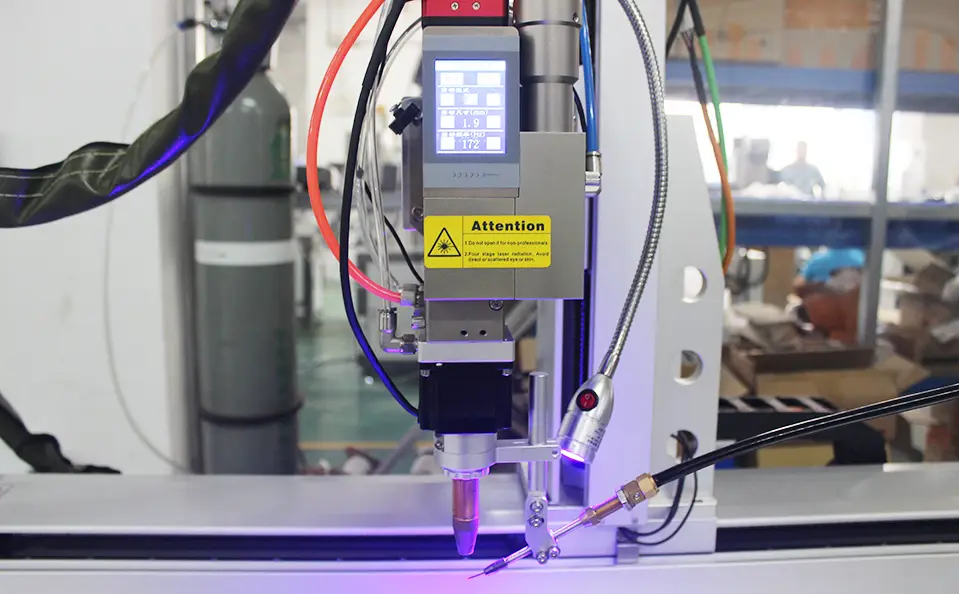

High performance laser welding head

The special customized laser welding head can realize spot welding, butt welding, lap welding, sealing welding and other welding + aiming combination design for thin-walled materials and precision parts, visual CCD acquisition, integrated infrared sensor, and precise visual positioning

Automatic wire feeder

The wire is stable without slipping, automatic synchronous welding, parameters can be adjusted, under the control of microcomputer, it can continuously and stably send out the automatic wire feeding device according to the parameters set by the welding operator.

Versatile Welding Capabilities

The Platform CNC Laser Welding Machine is an innovative tool that can handle a wide range of welding projects. With its precise laser technology, this machine is capable of welding different types of metals, including aluminum, copper, and stainless steel. Whether you need to weld thin sheets or thicker materials, this machine is up for the task. The Platform Laser Welding Machine also has a large platform that can accommodate various sizes of workpieces, making it ideal for welding large components or multiple small parts at once.

User-Friendly Features

This laser welding machine is designed with user-friendliness in mind. It has a user-friendly interface that makes it easy to operate, even for beginners. The machine’s LCD display provides clear and easy-to-understand information, allowing users to set the welding parameters quickly and accurately. The Platform CNC Laser Welding Equipment also has a stable welding platform that ensures accuracy and precision during the welding process. With its adjustable welding head and different welding modes, users can customize the machine’s settings to match their specific welding requirements.

Cost-Effective and Time-Saving

Investing in the Platform CNC Laser Welding Machine is a cost-effective decision for businesses of any size. With its high-speed welding capabilities, this machine can significantly reduce the welding time, increasing productivity and efficiency. Additionally, the machine’s low energy consumption and minimal maintenance requirements make it an economical choice. Its compact design also makes it easy to store and transport, saving valuable space in the workspace.

See for yourself and get a comprehensive test report.

TECHNICAL SPECIFICATIONS

| Model series | MQHJ series | |

|---|---|---|

| model | MQ HJ -1500 HY | MQHJ -2000 HY |

| laser power | 1500W | 2000W |

| Laser wave length | 10 8 0 + 10 nm | |

| Operating mode | series | |

| Power adjustmentrange | 10 ~ 100% | |

| Fiber corediameter | 25 or 50 | |

| xyz itinerary | 500mm *300mm *300mm | |

| Aiming and positioning | CCD | |

| Fiber length | 10m | |

| Repeatability | ±0.02 | |

| welding speed | 5 ~ 300mm/s | |

| Applicable thickness | < 6mm( depending on material and power) | |

| Wire Feeder | customizable Wire feeding speed 38 ~ 600 mm/min | |

| Wire diameter | 0.8/1.0/1.2/1.6/2.0mm | |

| cooling method | water cooling | |

| working environment | 10 ~ 40 ° C , humidity 10 ~ 85% , non - condensing | |

| rated power | 3KW | 5KW |

| Operating Voltage | 220 ± 20V ,AC ,PE ,50 /60Hz | |

| Dimensions | 1150 X 630 X 1080 mm | |