Laser marking has revolutionized how we mark and label various materials, and its applications are equally impressive when it comes to foil. Laser marking for foil involves using a high-powered laser beam to create permanent, precise, and durable markings on the surface of different foil materials.

This ultimate guide will delve into the world of laser marking for foil, exploring the techniques, benefits, equipment, and various applications of this cutting-edge technology. Whether you’re new to laser marking or looking to expand your knowledge, this guide will provide valuable insights into the world of laser marking for foil.

Understanding Foil Materials

What is Laser Marking for Foil?

Laser marking for foil is a non-contact process that uses a focused laser beam to create permanent markings on the surface of foil materials.

The laser beam interacts with the foil, causing localized heating and oxidation or color change, resulting in clear, high-contrast markings.

This technique allows for precise and intricate designs, text, and other markings on various sizes and shapes of foils.

Importance of Laser Marking for Foil Applications

The importance of laser marking for foil applications cannot be overstated. Laser marking provides several key benefits, making it a preferred choice in packaging, manufacturing, and product branding.

It offers enhanced durability and longevity of the markings, ensuring they resist fading, smudging, and wear over time.

Laser-marked foils also exhibit high precision and accuracy, enabling clear and legible markings, essential for branding, traceability, and compliance purposes.

Benefits of Laser Marking for Foil

Common Types of Foil for Laser Marking

When it comes to laser marking for foil, there are various types of foil materials available. Aluminum, stainless steel, and copper foil are commonly used in different applications.

Each foil type has unique properties and characteristics that make it suitable for specific purposes.

Properties and Characteristics of Foil Materials

Foil materials used for laser marking possess specific properties that contribute to their suitability.

Aluminum foil, for example, is lightweight, resistant to corrosion, and offers excellent thermal conductivity.

Stainless steel foil provides durability, corrosion resistance, and high strength. On the other hand, copper foil offers excellent electrical conductivity and is often used in electronic applications.

Laser Marking Techniques for Foil

Enhanced Durability and Longevity

One of the significant advantages of laser marking for foil is its enhanced durability and longevity. Laser-etched markings on foil are highly resistant to fading, smudging, and wear, ensuring the longevity of the markings even under harsh conditions.

This durability is particularly important for applications where foils are exposed to environmental factors such as moisture, temperature fluctuations, or rough handling.

High Precision and Accuracy

Laser marking enables high precision and accuracy, allowing for intricate and detailed foil markings.

Whether it’s a small text, logos, barcodes, or complex designs, laser marking technology ensures that the markings are sharp, clear, and aesthetically pleasing.

This level of precision is crucial for applications requiring product identification, branding, or regulatory compliance.

Resistance to Fading and Smudging

Traditional marking methods, such as printing or ink-based processes, can be susceptible to fading or smudging over time.

Laser marking eliminates these concerns by creating permanent, indelible markings on the foil surface.

The high-contrast and high-resolution nature of laser marking ensures that the markings remain intact and legible, even when exposed to external factors such as UV light, moisture, or chemical agents.

Laser Marking Equipment for Foil

Fiber Laser Marking

Fiber laser marking systems are commonly used for marking foils. These systems utilize a fiber laser source that produces a high-energy laser beam, which is then focused and directed onto the foil surface.

Fiber lasers offer high efficiency, reliability, and compact size, making them suitable for various foil marking applications.

CO2 Laser Marking

CO2 laser marking systems are also utilized for marking foils, especially when high power and continuous wave operation are required.

CO2 lasers emit a laser beam in the infrared range, which is well-absorbed by various types of foils. These lasers provide excellent control and versatility for different marking needs.

UV Laser Marking

UV laser marking systems are designed for high-precision and high-contrast marking on various materials, including foils.

UV lasers operate at a shorter wavelength, allowing for finer details and smaller spot sizes. They are often used when marking foils with complex patterns, small characters, or intricate designs.

Preparing Foil for Laser Marking

Types of Laser Marking Machines for Foil

When it comes to laser marking for foil, different types of laser marking machines are available, each with its capabilities and features.

Some machines are specifically designed for foil marking applications, offering specialized functions to optimize the marking process.

Choosing the right machine that aligns with your specific requirements and the type of foil material being marked is essential.

Factors to Consider When Choosing Equipment

When selecting laser marking equipment for foil, several factors should be considered. These include power output, wavelength, marking speed, beam quality, software capabilities, cooling system, and compatibility with different foil materials.

Evaluating these factors will ensure that the chosen equipment meets the specific marking needs and provides optimal results.

Designing Laser Markings for Foil

Surface Preparation Techniques

Before laser marking, proper surface preparation of the foil is crucial for achieving high-quality results.

Surface cleaning techniques such as wiping, brushing, or solvent cleaning can remove any dirt, dust, or oils that may interfere with the marking process. This ensures a clean surface for optimal laser interaction and adhesion of the markings.

Cleaning and Priming Methods

In addition to surface cleaning, certain foils may require additional treatments for better marking results.

Priming methods, such as applying a thin coating layer or pre-treatment solutions, can enhance the interaction between the laser beam and the foil surface.

These priming methods improve the laser markings’ contrast, adhesion, and durability.

Laser Marking Process for Foil

Creating Effective Designs for Foil Marking

Designing effective markings for foil requires careful consideration of factors such as size, font style, readability, and aesthetic appeal.

Clear and legible text, high-resolution graphics, and proper positioning of the markings are essential for achieving the desired outcome.

Software tools and design applications can aid in creating and optimizing designs specifically tailored for laser marking on foil.

Optimizing Visibility and Legibility

Optimizing the contrast between the marking and the foil surface is important to ensure maximum visibility and legibility of laser markings on foil.

Choosing the right laser parameters, such as power, speed, and frequency, can help achieve the desired contrast while avoiding undesirable effects, such as excessive heat or damage to the foil.

Adjusting these parameters based on the specific foil material and design requirements will ensure optimal visibility and legibility of the markings.

Applications of Laser Marking for Foil

Step-by-Step Guide to Laser Marking Foil

A step-by-step guide to laser marking foil involves several key considerations. These include material selection, surface preparation, machine setup, and design optimization. Here’s a simplified breakdown of the process:

Material Selection: Choose the appropriate type of foil based on the specific application requirements. Consider factors such as material thickness, composition, and surface finish.

Surface Preparation: Clean the foil surface using suitable techniques such as wiping, brushing, or solvent cleaning to remove contaminants that may hinder the marking process.

Machine Setup: Select the right laser marking machine based on the type of foil and the desired marking results. Configure laser parameters, power, speed, and frequency, to achieve the desired contrast and legibility.

Design Preparation: Using specialized design software, create or import the design to be laser marked on the foil. Optimize the design for high resolution and adjust it according to the foil’s size and shape.

Marking Process: Position the foil correctly within the laser marking machine. Initiate the marking process, and the laser beam will interact with the foil surface to create permanent markings.

Inspection: After marking, inspect the foil to ensure the quality and accuracy of the markings. Verify that the contrast and legibility meet the desired standards.

Finishing and Protection: Depending on the application, consider adding additional protective coatings or treatments to enhance the durability of the markings and protect them from external factors.

Safety Precautions and Best Practices

Laser marking for foil requires adherence to strict safety guidelines to protect operators and maintain the integrity of the marking process. Some essential safety precautions and best practices include:

They provide operators with appropriate safety gear, including protective eyewear and gloves.

Ensuring the laser marking area is well-ventilated to minimize exposure to fumes or particles generated during the marking process.

We are implementing lockout-tagout procedures to prevent accidental activation of the laser during maintenance or adjustments.

She regularly inspects and maintains laser marking equipment to ensure safe and reliable operation.

Case Studies: Laser Marking Success Stories for Foil

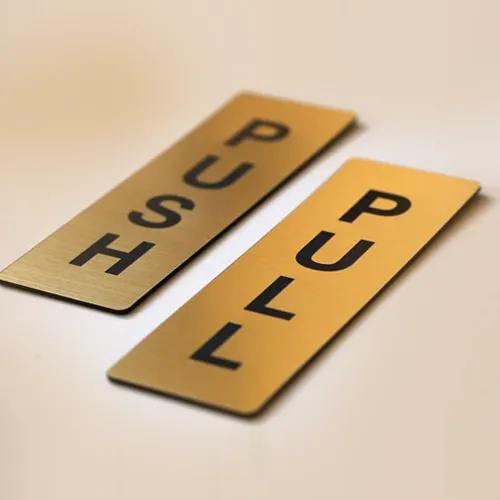

Product Branding and Labeling

Laser marking on foil is pivotal in product branding and labeling in the consumer goods industry. Manufacturers use laser marking to add company logos, product names, and essential information to foil-packaged items. The precise and permanent markings enhance the product’s aesthetics and serve as an effective means of brand identification and authenticity.

Packaging and Security Features

The packaging industry extensively employs laser marking on foil to add product security features. Foil with custom holographic markings, unique identification codes, or tamper-evident seals helps prevent counterfeiting and product tampering. Laser marking allows for complex and intricate designs that are difficult to replicate, thus safeguarding consumer trust and product integrity.

Industrial and Manufacturing Uses

In the industrial and manufacturing sectors, laser marking on foil is utilized for marking serial numbers, part codes, and batch information on metal components and parts. The permanent markings enable traceability, quality control, and compliance with industry standards. The durability and resistance to harsh environments make laser-marked foils ideal for various industrial applications.

Troubleshooting Common Issues in Laser Marking for Foil

Real-world Examples of Laser Marking on Foil

Let’s explore some common issues that may arise during the laser marking process for foil and how to troubleshoot them:

Uneven Marking: Uneven markings can result from inconsistent laser power or focus. To address this, ensure the laser is properly calibrated and the foil is placed flat and at the correct focal distance.

Excessive Heat or Burning: Excessive heat or burning on the foil may occur if the laser parameters are too high. Adjust the laser power and speed settings to prevent overheating and ensure a clean marking.

Conclusion: Harnessing the Power of Laser Marking for Foil

In conclusion, laser marking for foil offers numerous advantages that make it an indispensable technology in various industries. From enhanced durability and precision to resistance against fading and smudging, laser marking provides long-lasting, high-quality markings on foil materials.

With different laser marking techniques and equipment, businesses can choose the most suitable options. By understanding the importance of surface preparation, design optimization, and proper maintenance, the full potential of laser marking for foil can be harnessed.

As technology advances, the future of laser marking for foil looks promising. Regulatory considerations and compliance with industry standards will shape the development of this technology, ensuring its continued growth and integration into various applications.

With its ability to deliver permanent and precise markings, laser marking for foil is set to play a pivotal role in product branding, security, and traceability.